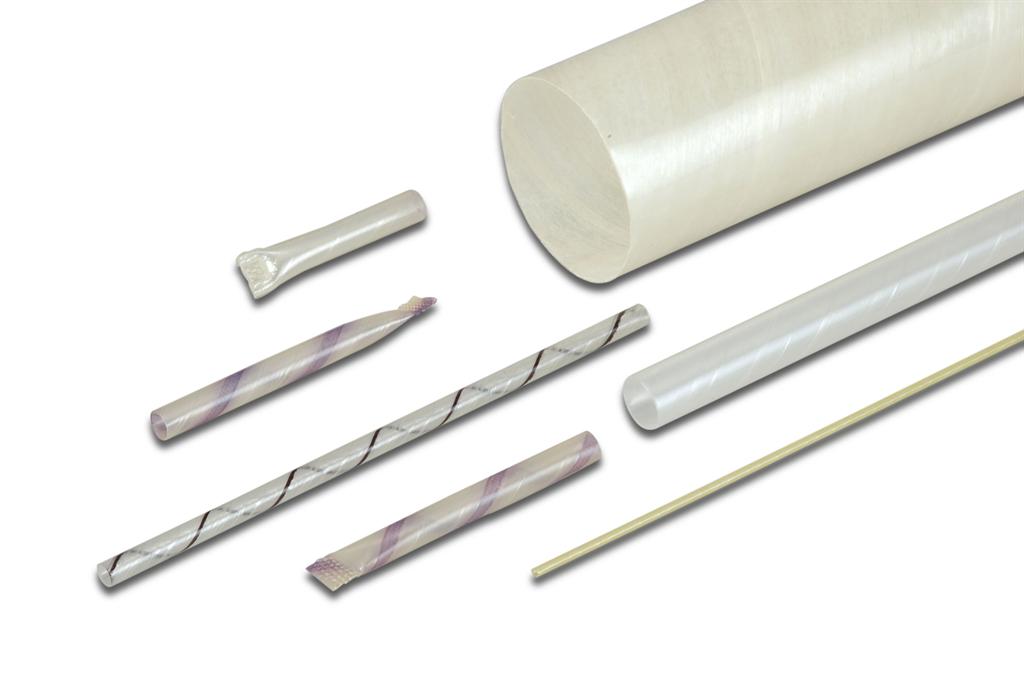

Battery Sleeve Insulation

Battery Sleeve Insulation | Battery Insulation | Battery Sleeve | Battery Sleeves | Battery Tubes

Precision Products Group, Inc has a 30 year history of supplying some of the world’s leading battery manufacturer’s with their battery sleeving and battery end-caps solutions. As materials and manufacturing specialists, Precision Products Group engineers are uniquely qualified to work with you in designing cost effective solutions for your battery insulation requirements. From low temperature papers like dielectric kraft, to moisture and/or flame retardant materials or even PET, PET-G combination materials to high temperature polymers like Kapton and Nomex, we have the products and the packaging that offer the protection your products depend on. These materials can be enhanced through our internal printing, notching and forming, spooling and ultrasonic sealing capabilities. Whether your need is for thermal, electrical or environment protection, let us design a custom battery sleeve or battery end-cap for your application.

Materials

|

Polyester Shrinkable Sleeving

|

150 C

|

|

Polyamide (Nomex)

|

220 C

|

|

Nomex / Mylar Combinatio

|

180 C

|

|

Polyimide (Kapton)

|

400 C

|

|

Electrical Kraft

|

105 C

|

Special Material Properties

- Polyimide - Extreme Heat Resistant

- Polyester - Dialectric Barrier

- Krafts - Flame / Moisture Retardant

Applications

| Portable Radio Communications |

Global Positioning Systems |

| Transponders |

Transmitter Beacons

|

| Thermal Imaging |

Telemetry

|

Digital Messaging Devices

|

Target Acquisition Systems |

| Night Vision Equipment |

Surveillance |

| Navigation Subsystems |

Chemical Detection

|

| Remote Sensors |

Memory Backup |

| Firing Systems |

Cordless Power Tool Batteries |

Automotive

|

Appliances

|

| Battery Tubes |

Battery Sleeve Insulation |

| Battery Sleeve |

Battery End Caps |

We can also shrink groups of cells together in a series for medical, military, and custom battery applications..

For more information on our battery sleeve insulation, battery end caps, and battery sleeving,

contact PPG